What is “Sticky Shed Syndrome”?

(AKA “Archival Shed”)

Information drawn from Wikipedia: http://en.wikipedia.org/wiki/Sticky-shed_syndrome, 10/24/2013

Video is from SoundImages.com. It runs 1 minute, 17 seconds.

Sticky-shed syndrome (also called “Archival Shed”) is a condition created by the deterioration of the binders in a magnetic tape, which hold the iron oxide magnetizable coating to its plastic carrier. This deterioration renders the tape unusable. Some kinds of binder are known to break down over time, due to the absorption of moisture (hydrolysis). The symptoms of this breakdown are immediately obvious even when rewinding the tape: tearing sounds and sluggish behavior. If a tape with sticky-shed syndrome is played, the reels will make screeching or squeaking sounds, and the tape will leave dusty, rusty particles on the guides and heads.

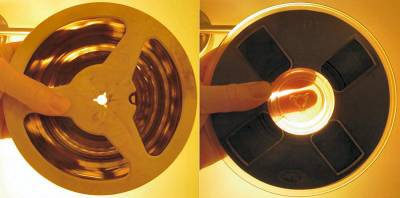

Magnetic audio reel-to-reel tapes: acetate backing on the left, and polyester backing on the right. Light can be seen coming through the tape windings of the tape with acetate backing. Acetate backing is chemically less stable than polyester backing, but also does not suffer from sticky shed syndrome.

Most tapes affected by Sticky Shed are those that were made by Ampex such as 406/407, 456/457, 499, and consumer / audiophile grade back-coated tapes such as Grand Master and 20-20+. Many tapes made by Scotch/3M are also affected and the most common offenders here are the “pro” tapes such as 206/207, 226/227, 808, and 986 as well as audiophile tapes such as “Classic” and “Master-XS”.

Baking is a common practice for temporarily repairing sticky-shed syndrome. There is no standard equipment or practice for baking, so each engineer is left to create their own methods and materials. Generally, tapes are baked at low temperatures for relatively long periods of time, such as 120-130°F for 4-48 hours. It is commonly thought that baking a tape will temporarily remove the moisture that has accumulated in the binder. A treated tape will reportedly function like new for a few weeks to a few months before it will reabsorb moisture and be unplayable again. It is recommended, however, that the playback should be done within a week or two. Baking cannot be used with acetate tapes.

A lot of tape manufactured in the mid 1970’s to early 1980’s is starting to come out of storage now for re-mixing and re-issue, and engineers are finding that it won’t play. The surface of the tape has become gummy and it sticks to the heads and fixed guides of the tape transport, squealing, jerking, and, in extreme cases, slowing down or stopping the tape transport. This problem has cropped up on all brands of tape, but is nearly always fixable, at least temporarily by baking the tape.

Tapes deteriorate because of a breakdown in the binder (the glue) that holds the oxide atoms on the tape. The binder contains polyurethane, which soaks up water and causes the urethane to rise to the tape’s surface. This problem is known as the “sticky-shed syndrome.” Short strands of urethane were most commonly used in tapes (until it was discovered that middle-sized strands are better) and were good at absorbing moisture. Baking the tape temporarily restores the tape so that it can be safely copied to another tape or a different format.

After baking, the tape usually remains in good condition for approximately a month. If the tape re-deteriorates,it may be possible to bake the tape again.

There are some important signs that show when a tape needs baking. The typical symptom is squealing when the tape passes the playback heador other fixed parts of a tape player. The squealing is audible directly from the tape and also transmitted electronically through the output of the tape recorder. Continuous use of a squealing tape risks permanently damaging the tape, as oxide is sometimes torn off the tape. This flaking residue can be seen and can feel gummy while still on the tape’s surface. There is also a risk of damage to the player. Another symptom is the tape sounding dull and distorted.

Deterioration can happen to any tape, but the problem is more common with audio recording tape manufactured in the USA from the mid 1970’s to the early 1980’s. Tapes that often need baking:

- AMPEX: 406, 407, 456, 457, 499, Grand Master

- 3M: 153, 206, 207, 208, 209, 217, 219, 226, 227, 806, 807, 808, 809, Classic DP, Classic LP, Classic SP, Master and Master SX